ChemResist

Many years of experience with ChemResist

Rudolf Gutbrod GmbH sets standards early on as one of the leading fluoropolymer processors in Europe. Customer orientation is given a major priority at Rudolf Gutbrod GmbH. Many years of practical experience, consistent development of new technologies and a cooperation marked by flexibility, open-mindedness and commitment are also just as important for Rudolf Gutbrod GmbH.

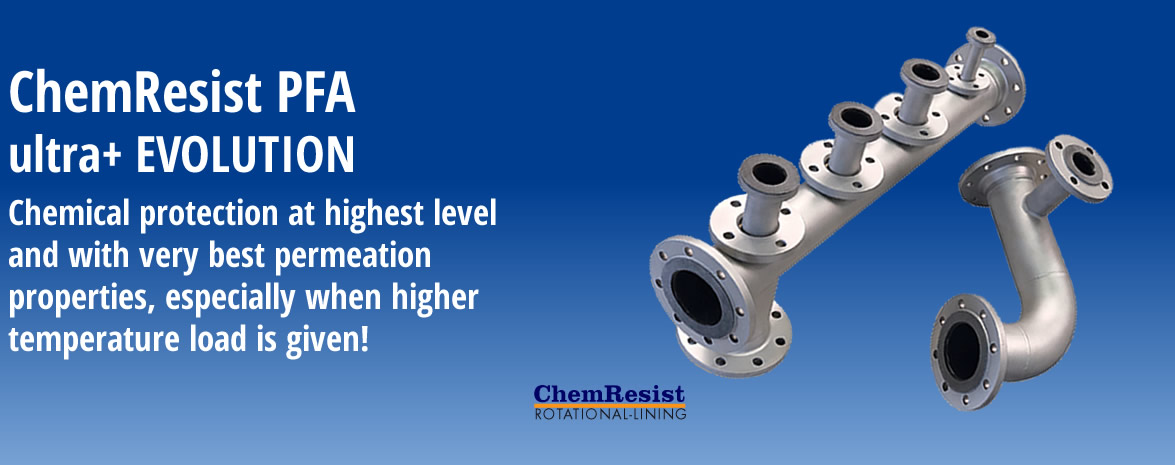

Rudolf Gutbrod GmbH is a pioneer in lining technology with its innovative and economic product “ChemResist Rotational Sinter Lining”. Quite often the conventional lining and coating technologies available in the market do not fulfil the many requirements placed on them. ChemResist puts a new emphasis in this case using a process and computer-controlled lining technology according to the rotational sinter lining process. This procedure creates a seamless lining with virtually uniform lining thickness.

Applications

High-quality fluorinated materials like ETFE, PFA and the Thermoplast PE, are used by ChemResist. ETFE and PE are also available as electrically conducting versions. ChemResist ETFE is FDA- and EU-conform. This also applies to electrically conductive specifications.

Partly and fully fluorinated polymers offer universal and permanent resistance to acids, alkalis, solvents and chlorides. ChemResist possesses an extremely smooth and anti-adhesive surface and thus prevents bacterial adherence or growth.

In the manufacture of highly pure products (chip industry, high purity grade chemicals) ChemResist prevents impaired quality from foreign substances or dissolved metallic ions.

If special parts are to be lined, ChemResist possesses distinct advantages both from an economic as well as a qualitative point of view. The process can be adapted flexibly to the circumstances or requirements (preparation of tooling is not required). Even rigid construction specifications can be solved economically with ChemResist.

Mechanical preliminary work, as well as the use of adhesives, can be avoided. Chemical resistance and high temperature resilience remain unaffected. The permanent and homogeneous lamination to the substrate means new and interesting perspectives in use under vacuum.

ChemResist opens up new and versatile options for surface protection in almost all areas of in dustry to the user and the planning engineer.