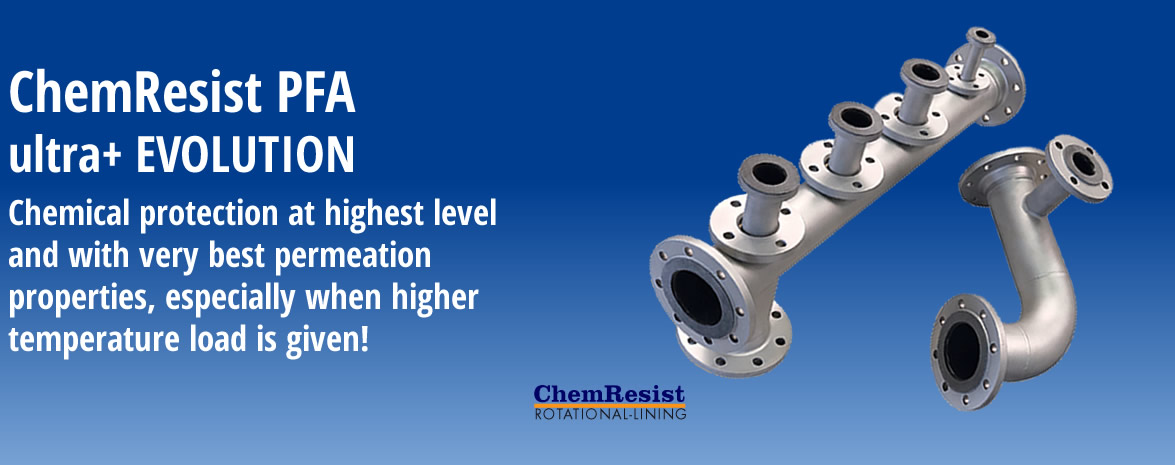

ChemResist - Advantages

Decisive advantages of ChemResist with the materials ETFE, PFA and PE

Layer thicknesses up to 5 mm are possible

In conventional coating of components, the layer thickness is limited to approx. 1 mm. With the Gutbrod “ChemResist” system, wall thicknesses of up to 5 mm can be achieved.

Seamless lining

Complex and difficult parts do not represent a problem for ChemResist. All surfaces of the workpiece are reliably lined with specific biaxial movements. The result is a perfect and homogeneous lining without seams and welding points.

Reduced residual tension

As no pressure is required during the lining process, considerably less tension remains in the workpiece.

Optimally adhering coating

ChemResist requires no adhesive, and no joints are produced either. The permanent and homogeneous lamination to the substrate means new and interesting perspectives in use under vacuum. For special applications in the high temperature range, a very thin primer may be used.

Small lot sizes are also economical

It is also possible to complete small lot sizes economically using the technical rotation technology, even if there is a broad spectrum of complex forms and sizes.

Cost-effective despite quality improvement

The steel construction can be planned considerably more cost-effectively. By reducing the flange connectors (and thereby the number of potential leakage points), quality can be increased considerably.

Long-term safety

Homogeneous and permanent lamination to the substrate is achieved without the danger of collapsing with larger diameters. No safety risk through impact and longitudinal expansion, even at temperatures less than 0° C.

Quality assurance in every dimension

ChemResist permits components to be lined regardless of the design up to a size of 5,000 mm in length, a diameter of up to 3,500 mm and a total weight of 3,500 kg, without rigid requirements on the construction itself, larger and heavier parts on demand. The process sequence with entry and processing data is documented in detail.

Comparison with conventional coating and lining processes

Perfect solutions with ChemResist

Effects of temperature on ChemResist